How AI-Powered Applications Benefit Manufacturing Companies

Introduction

Modern manufacturing companies transform digitally. Some of the reasons behind this transformation include addressing intensifying competition and meeting the ever-changing requirements of customers. Globally, manufacturers consult a reputed AI ML development company to drive growth through transformation.

As we have entered into the era of intelligent manufacturing, AI-powered apps are ready to play a vital role. AI is no longer a futuristic aspiration but becomes a part of business strategy to lead in the thriving manufacturing sector. This post will dive into the scope and benefits of AI development services for the manufacturing sector.

Scope of AI in Manufacturing Sector

AI has vast scope in the manufacturing sector as it touches almost every aspect of the value chain. This technology can make manufacturing processes more intelligent, adaptive, and efficient. Whether it is quality control or workforce safety, resource optimization or sustainability, AI app development services can assist manufacturers in managing various activities. This are the key reasons AI has started gaining prominence in the manufacturing market over the period.

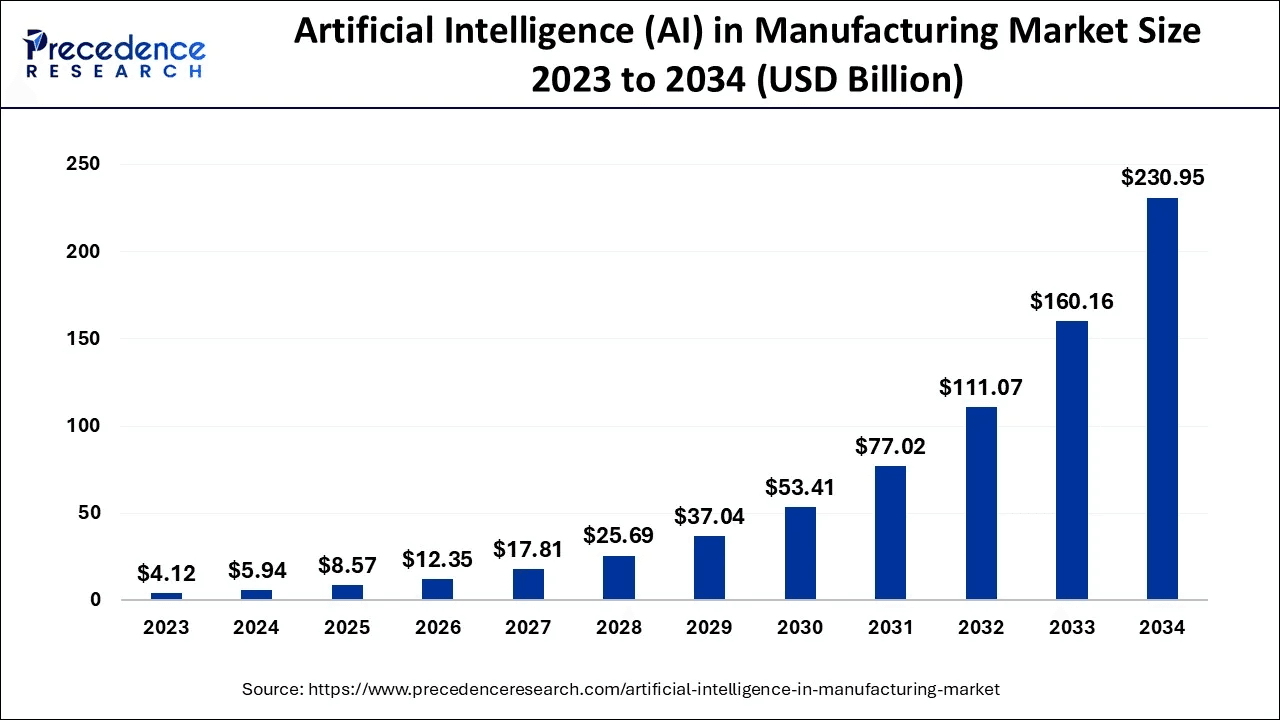

As per the recent research report, the market size of Artificial Intelligence in manufacturing is expected to cross USD 230.95 billion by 2034 with a CAGR of over 44 percent. The following graph shows steady rise in the market size of AI in manufacturing market.

Source: Precedence Research

Let’s go through some top benefits of AI-powered apps in the manufacturing industry.

Key Benefits of AI-Powered Apps in Manufacturing Sector

AI-based apps are becoming indispensable tools for the manufacturing industry. Here are the top reasons why more manufacturers opt for AI app development services-

Enhanced Efficiency

AI-powered apps can automate repetitive tasks and streamline production cycles. These apps ensure more speed and accuracy in every process, from inventory to supply chain management and maintenance to machine calibration. As a result, a manufacturing company can get higher throughput with reduced time-to-market.

Moreover, AI enables manufacturers to monitor various processes in real time. They can respond quickly to any bottlenecks or changes in trends.

Improved Quality Control

One of the biggest benefits of AI apps for the manufacturing sector is they can detect anomalies or issues without human intervention. In other words, AI-driven manufacturing apps can monitor the manufacturing system more accurately and effectively. It results in reducing waste and enhancing brand reputation.

Furthermore, AI models can analyze various patterns related to quality control and help manufacturers find root causes across the entire production cycle.

Optimized SCM

Supply chain management plays a crucial role in ensuring the success of the manufacturing company. AI-driven analytics is useful for managing inventory and finding optimal logistics routes. Manufacturers can reduce delays and avoid conditions like overstocking or stockouts with the help of AI-powered features.

AI apps with these features can make the entire supply chain more resilient and agile, optimizing its core processes.

Predictive Maintenance

Predictive analytics is one of the most popular functionalities of AI technology. AI models can analyze sensor and machine data to predict potential failures in advance. This results in a proactive approach for equipment maintenance, and manufacturers can minimize downtime.

The predictive maintenance feature can also extend equipment lifespan and manufacturing companies can get seamless operations across the floor.

Reduced Operational Costs

Automation and resource optimization are crucial for reducing operational costs. AI-based apps can help manufacturers cut labor costs and avoid unnecessary repairs, improving the bottom line. Manufacturing companies can cut labor costs by achieving automated resource optimization.

Moreover, AI apps can also suggest eco-friendly policies by analyzing daily energy consumption and material use. These apps can help organizations save money and increase sustainability while effectively following regulatory compliance.

Personalized Experiences

Manufacturers can offer personalized experiences to employees through interactive dashboards and engaging user interfaces in AI apps. Whether it is about getting custom insights or role-based alerts, AI apps can manage every task effectively. It results in improved collaboration and decision-making process across different departments.

Personalized AI interfaces are also beneficial in improving user adoption. AI-enabled apps can increase the user’s efficiency and confidence over the period.

Though AI-powered apps offer many benefits to the manufacturing industry, it is essential to address major AI adoption-related challenges. A reliable AI development services provider follow the best practices to address these challenges effectively.

Key Challenges and Considerations of AI Adoption

AI development services need to handle some challenges and consider major aspects for ensuring effective adoption.

Data Availability and Quality

AI systems require a large volume of high-quality data. However, in the manufacturing sector, incomplete and inconsistent data is quite common. This can limit the effectiveness of AI apps, and companies may not get accurate insights.

Manufacturers can invest in data infrastructure to improve data quality and increase its availability.

Integration with Legacy System

Outdated equipment and systems have little or no compatibility with modern AI apps. It is cumbersome to replace such legacy systems, and it remains costly. Manufacturers find it difficult to use their existing systems along with AI models.

Middleware or APIs can facilitate integration without overhauling the existing infrastructure.

Lack of Expertise

AI models need specialized knowledge. Mostly, manufacturing companies do not have skilled professionals who can integrate technological advancements into dedicated applications on the shop floor. This lack of expertise causes issues in maintaining apps as well.

Manufacturers can either upskill their existing staff or consult experienced AI app development service providers for end-to-end technical assistance.

High Initial Investment

AI adoption or AI app development requires upfront costs for purchasing software, hardware, and data infrastructure. This initial investment can cause a financial burden on startups and even SMEs. Furthermore, it is not possible to gain short-term ROI with AI applications.

It is better to start with small-scale pilot projects to understand value and explore the scope of AI apps.

Workforce Resistance

This is the most common challenge for AI adoption. Fear of job displacement among workers who have minimal knowledge of digital tools can trigger this resistance. It can slow down or derail the AI adoption process in the manufacturing sector.

It is better to communicate with employees and involve them in AI-driven transformation. Transparency can enhance trust among employees.

Risk of Hacking

Increased connectivity and massive data collection can increase the risk of hacking or cyberattacks. Manufacturing systems remain vulnerable to such attacks due to their interdependent networks and systems. The risk of hacking looms large on AI apps, especially if they have personal information of employees, stakeholders, or customers.

Manufacturing companies can adopt strong cybersecurity measures including endpoint protection and real-time monitoring of AI systems. Regular audits are also useful for mitigating cybersecurity-related risks.

A trusted AI/ML development company can assist manufacturing companies to address these challenges and implement considerations.

Role of Silicon IT Hub in Adopting AI in Manufacturing through Apps

As a reputed AI app development company, Silicon IT Hub can assist manufacturers to implement this revolutionary technology. Our in-house team of experienced professionals remains by your side to meet the specific requirements and challenges of your manufacturing company.

We, at Silicon IT Hub, offer custom app development, smart quality control, and supply chain optimization under the hood of AI app development services. We ensure that your manufacturing company can leverage the benefit of AI as we follow standard practices in developing feature-rich applications.

Want to Boost Your Manufacturing Company with an AI-Driven App?

LET'S CONNECT!Concluding Lines

AI-powered applications benefit manufacturing companies in multiple ways. These user-friendly apps can optimize supply chain management and offer a personalized experience. However, it is essential to address big challenges like data availability and security to leverage the advantage of AI applications.

Have an Idea?Let’s Build It Together!

Have an Idea?Let’s Build It Together!